Automation Equipment

The role of automation equipment is very extensive and far-reaching,playing anirreplaceable role in improving production efficiency,ensuring product quality,reducing labor costs,enhancing work safety,and achieving intelligent production.

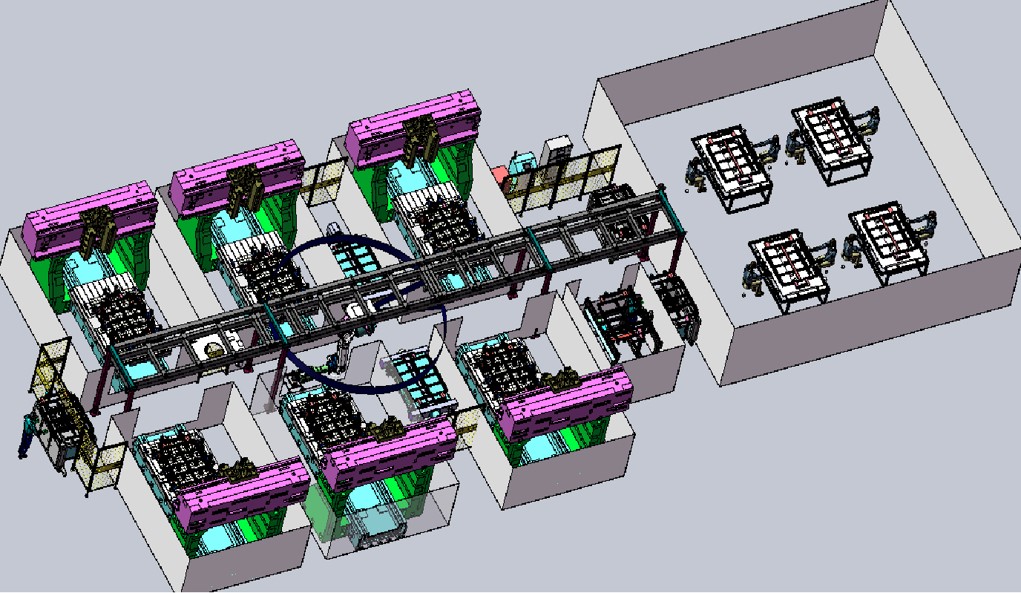

Automated Cleaning Machine

- Multi-slot water-based cleaning and oil immersion dehydration rust prevention equipment.

- Fully automated loading, unloading, cleaning, and conveying.

- Non-standard design based on cleaning products.

- Functions include ultrasonic cleaning (heating), rinsing, air drying, oil immersion, etc.

- Set up internal circulation ful process filtration in slot 5,with a working frequency of continuous operation.

- Set up liquid level monitoring for cleaning agents in the tank.

- Equipped with basket cleaning equipment visualization of 8 cleaning parameters.

Automatic Packaging Line

- Multiple tracks running simultaneously.

- PLC controls all motion modules.

- Non-standard customization: customers can set tracks according to site and select different conveyor belts.

- Equipped with advanced servo motor drive.

- Customers can choose different conveyor belts.

- Optional weighing, automatic unboxing, packing equipment, label printing.

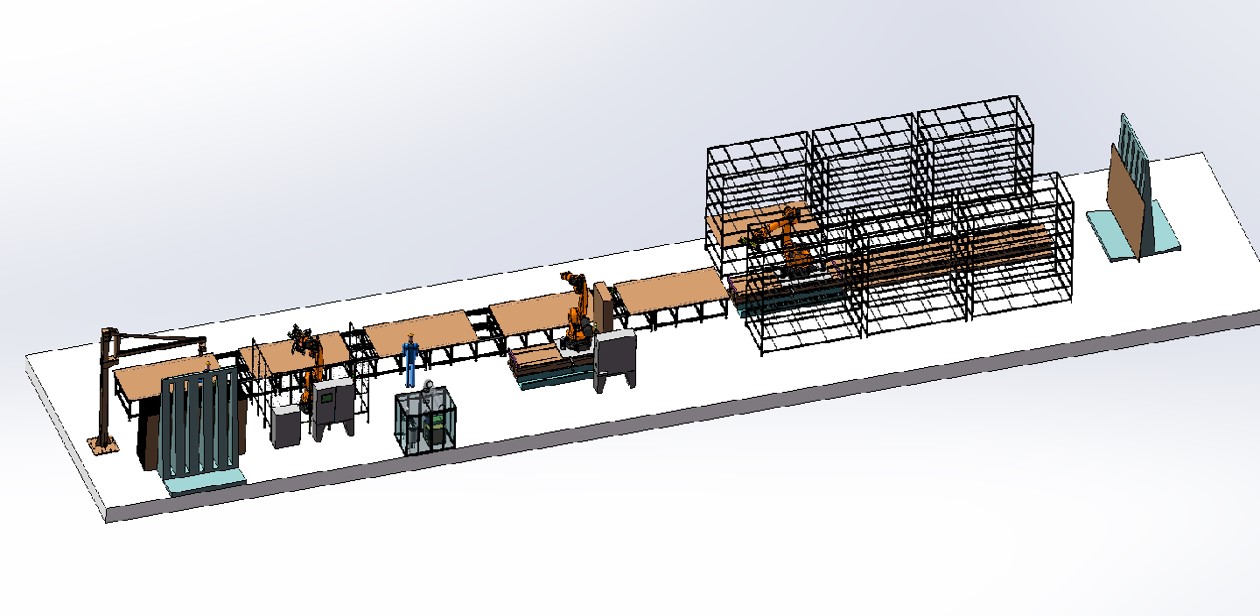

Automatic Welding Production Line

- Integrated welding production line workstation.

- PLC controls all motion modules.

- Main components include workstation body, robot, welding gun, PLC, positioner, etc.

- Robots for automatic welding to achieve stable welding quality and reduce safety risks.

- Occupies a small area of space,saving space.

- Visualization of welding parameters.

- Traceability function: automatically records welding parameters for traceability.

- Optional automatic loading and unloading equipment.

Automatic Processing Production Line

- Automation transformation of various processing equipment.

- Using suspended tracks for robot handling.

- Robots grab and place parts.

- Turntable settings.

- product flipping functions.

- Renovation of existing equipment safety doors.

- Non-standard claw design.

- PLC control cabinet controls all actions.

Automatic Painting Line

- Fully automatic spraying production line.

- Fully automatic loading and unloading.

- Automatic assembly function.

- Automatic glue application and curing stations.

- glue curing stations.

- Cleaning machine integrated.

- Non-standard claw design.

- PLC control cabinet for full process control.

Automatic Handling Machine

- Track length and hand cycle set according to actual needs.

- PLC controlled motion module.

- Non-standard customization based on handling weight and rhythm.

- Reduces labor costs, improves production automation level, and enhances safety.

- Design clamps according to non-standard product specifications.

- Optional selection of different robot models according to customer needs.

- Expansion:Can be used for cutting materials on production lines.